Why Ready-To-Use From Graffiti Foods

MADE FROM SCRATCH – Our products are made from scratch and fresh every day. We buy direct from the product sources in most cases, which gives our customers a fresher product. A recipe made from scratch is not pouring or mixing pre-made products from cans and jugs from a distributor.

MADE FROM SCRATCH – Our products are made from scratch and fresh every day. We buy direct from the product sources in most cases, which gives our customers a fresher product. A recipe made from scratch is not pouring or mixing pre-made products from cans and jugs from a distributor.

- CONSISTENCY OF PRODUCTS – We provide consistency of products so that each store gets the same recipe, with the same ingredients, from the same manufacturer, all the time, and every day.

- PROTECTS YOUR BRAND – Eliminates employees from leaving with your signature recipes for your concept and the high costs of training and retraining staff. There is virtually 100% turn over in labor in the restaurant business.

- LOWERS COSTS – We do not measure raw costs in the door; we measure finished costs on the plate. Inventory, handling, labor, clean up, yield loss, overhead, workman’s comp, server’s, food safety, and waste to name a few.

- REDUCES LABOR AND PREP TIME – So the focus is on execution and customers.

- REDUCES INVENTORY AND KITCHEN SPACE – Pre-made will lower your inventoried items and in some cases eliminate stock items and reduce your category items. May help reduce kitchen space and add tables for paying customers.

- ELIMINATES OUT OF STOCK

- REDUCES YIELD LOSS – You get 100% of what you ordered because you do not have to empty and transfer products from multiple containers.

- REDUCES WASTE AND CLEAN UP – With your recipes pre-made in pouches you have no clean up and pouches take up very little space which will reduce trash and trash pickup.

- WHY GRAFFITI FOODS – Working with Graffiti Foods gives you an additional culinary arm for product and menu development, intro to new markets, updates on industry trends, and focuses on food safety and food technologies.

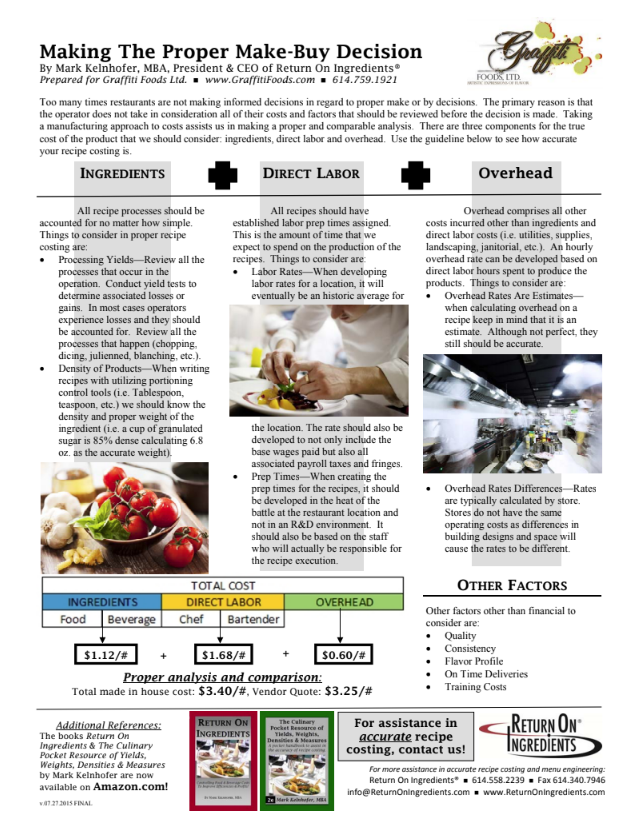

Making The Proper Make-Buy Decision By Mark Kelnhofer, MBA, President & CEO of Return On Ingredients® Prepared for Graffiti Foods Ltd.

Too many times restaurants are not making informed decisions in regard to proper make or buy decisions. The primary reason is that the operator does not take in consideration all of their costs and factors that should be reviewed before the decision is made. Taking a manufacturing approach to costs assists us in making a proper and comparable analysis. There are three components for the true cost of the product that we should consider: ingredients, direct labor and overhead. Use the guideline below to see how accurate your recipe costing is.